Smoked rubber, also known as ribbed smoked sheets (RSS), is a processed form of rubber that has been derived from unsmoked sheets. This unique material is widely used in various industries due to its exceptional qualities and versatility. In this article, we will delve into the uses and benefits of smoked rubber, shedding light on its importance in automotive engineering and other applications.

What is Smoked Rubber Used For?

Smoked rubber, specifically ribbed smoked sheets, is classified into different classes based on purity, elasticity, and color. The highest quality smoked rubber is denoted as RSS1, while lower quality variations are classified as RSS2, RSS3, RSS4, and RSS

One of the primary uses of smoked rubber is in the production of car tires. The strong, waterproof, and elastic nature of smoked rubber makes it an ideal raw material for manufacturing high-quality tires. The ribbed smoked sheets are processed further to create the tread design, providing improved traction and durability on various road surfaces.

Additionally, smoked rubber is also used in the production of conveyor belts, rubber pipes, shoes, and various automotive parts. Its elasticity and waterproof properties make it suitable for these applications, ensuring long-lasting performance and resistance to wear and tear.

What is Smoking Rubber?

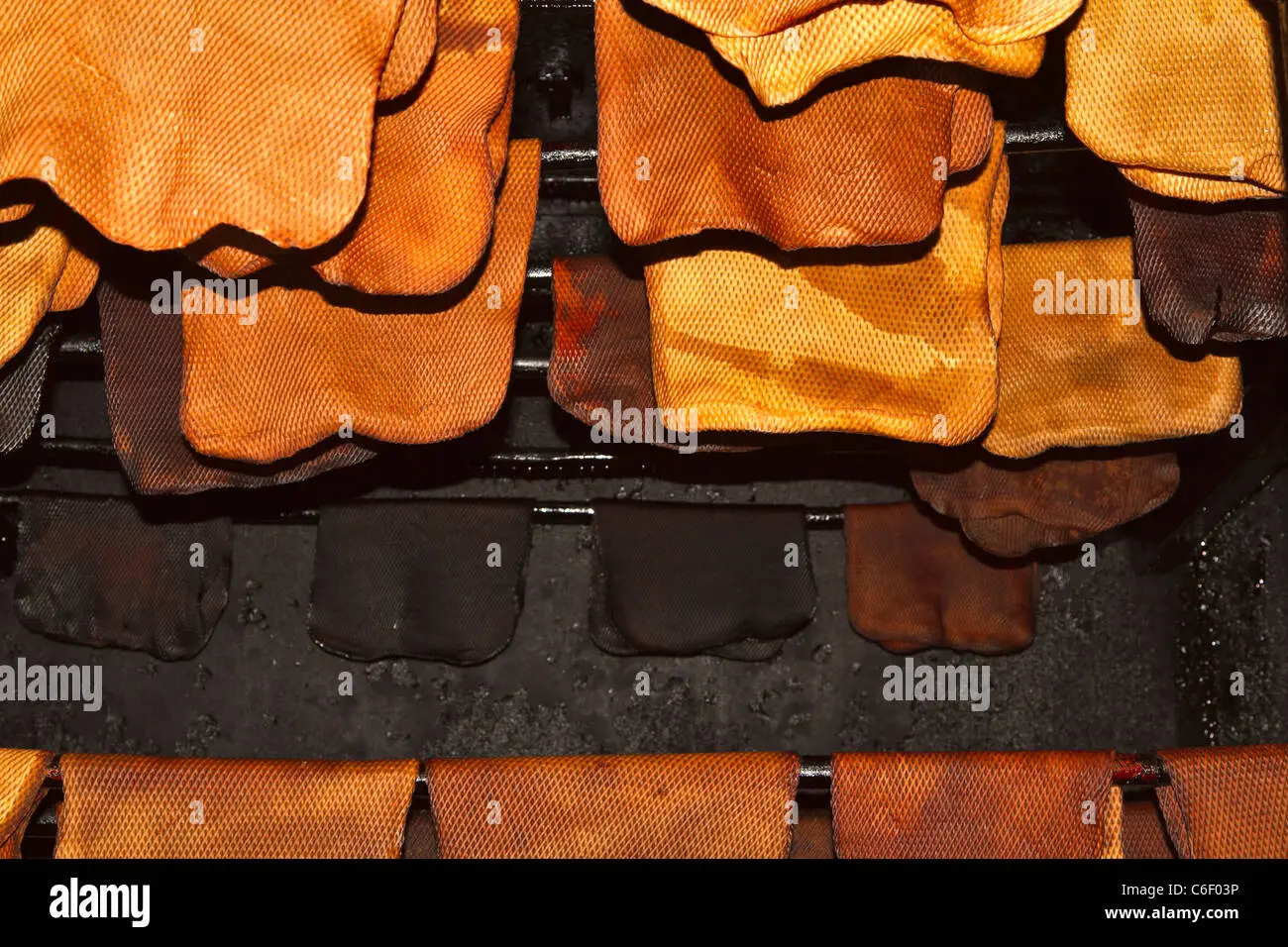

Smoking rubber is the process of transforming unsmoked sheets into ribbed smoked sheets. This process involves exposing the rubber sheets to smoke in a controlled environment. The smoke helps enhance the physical properties of the rubber, such as improving its elasticity and durability.

During the smoking process, the rubber sheets are hung vertically in a smokehouse. The smoke is generated by burning various types of wood, such as oak or pine, which release chemicals that react with the rubber. This reaction leads to the formation of cross-links within the rubber molecules, resulting in increased strength and elasticity.

The duration of the smoking process varies depending on the desired quality of the smoked rubber. Typically, the sheets are smoked for several days to achieve the desired level of purity and elasticity.

What Does Rubber Mean Slang?

In slang terms, the word rubber is often used to refer to a car tire. This usage stems from the fact that rubber is a primary material used in tire manufacturing. Car enthusiasts and mechanics commonly use the term rubber to discuss tire-related topics, such as tread patterns, tire compounds, and overall performance.

When a tire becomes worn out, it is common to replace only the tread rubber. This process involves vulcanizing new rubber onto the existing tire carcass, creating a new tread design. This not only helps in improving the grip and traction of the tire but also extends its lifespan.

What is the Full Form of RSS Rubber?

The abbreviation rss stands for Ribbed Smoked Sheet, which is the processed form of smoked rubber. RSS rubber is classified into different classes based on various factors, including purity, elasticity, and color. The highest quality smoked rubber is denoted as RSS1, while lower quality variations are classified as RSS2, RSS3, RSS4, and RSS

The classification of RSS rubber helps manufacturers and consumers identify the quality and suitability of the material for different applications. Higher-grade RSS rubber is often preferred for critical applications like high-performance tires, where exceptional elasticity and durability are required.

Frequently Asked Questions

- Q: Is smoked rubber eco-friendly?

- Q: Can smoked rubber be recycled?

- Q: Is smoked rubber suitable for extreme weather conditions?

A: Yes, smoked rubber is considered to be eco-friendly. It is derived from natural rubber, which is a renewable resource. Additionally, the smoking process does not involve the use of harmful chemicals, making it a sustainable option.

A: Yes, smoked rubber can be recycled. Rubber recycling processes involve grinding the smoked rubber and using it as a raw material for various applications, such as playground surfaces and rubber mats.

A: Yes, smoked rubber exhibits excellent resistance to extreme weather conditions. It can withstand both high and low temperatures, making it suitable for use in various climates.

In conclusion, smoked rubber, or ribbed smoked sheets (RSS), is a versatile material used in various industries. Its exceptional properties, such as elasticity, durability, and waterproof nature, make it an ideal choice for applications like tire manufacturing, conveyor belts, and automotive parts. The smoking process enhances these qualities, resulting in high-quality smoked rubber with different classifications. Understanding the uses and benefits of smoked rubber can help in making informed decisions when it comes to selecting materials for specific applications.

If you want to know other articles similar to Smoked rubber: uses & benefits in automotive engineering you can visit the Rubber category.

Related Articles