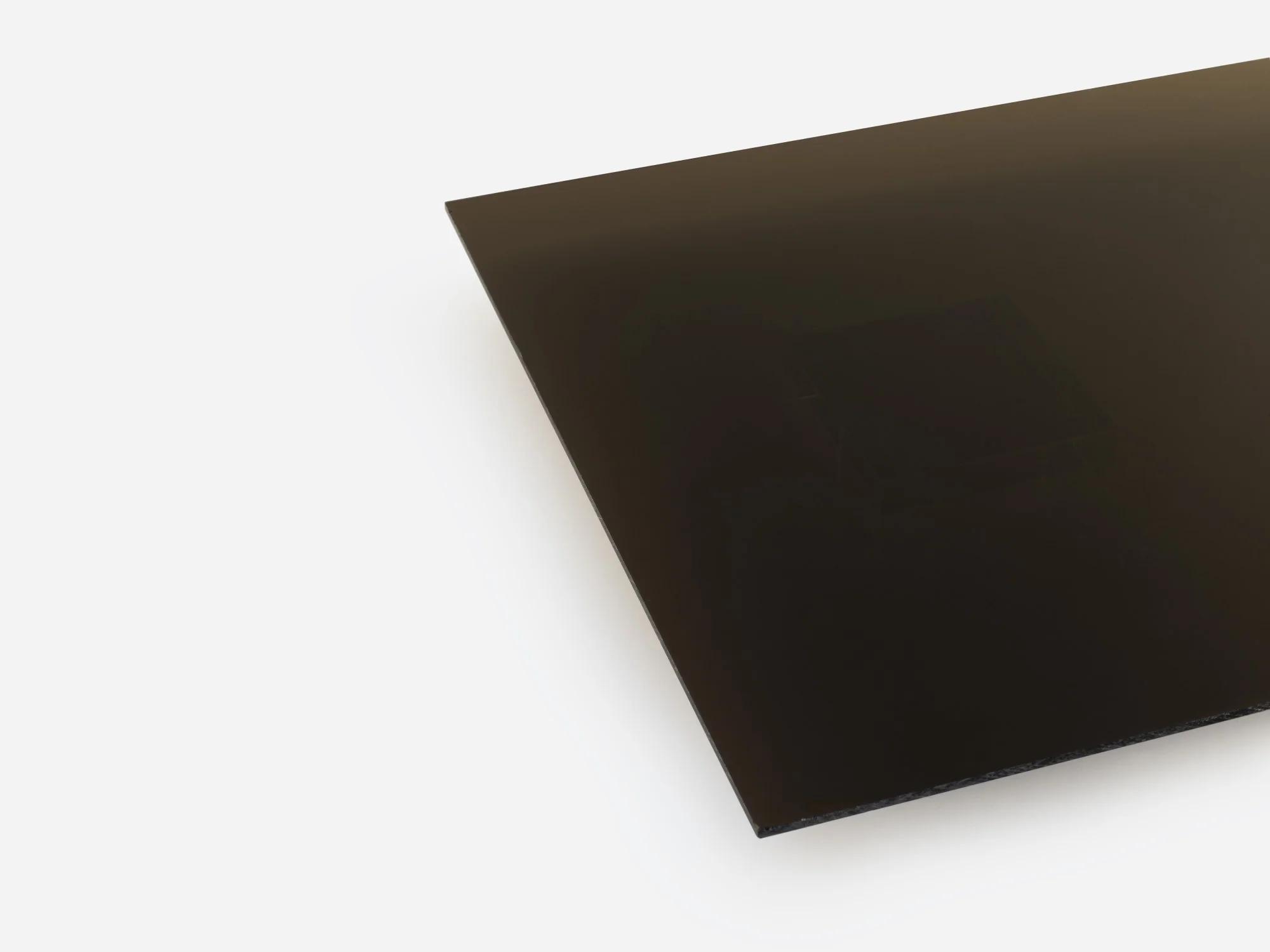

Acrylic sheet plastic, commonly known as Perspex, is a versatile and durable material that is often used in a wide range of applications. One of the key advantages of acrylic sheets is that they can be easily cut to size, allowing for customization to fit specific project requirements. In this guide, we will explore the process of cutting smoked Perspex and provide tips and recommendations for achieving clean and precise cuts.

The Benefits of Cutting to Size

When working on various projects, having acrylic sheets cut to size offers several benefits. By cutting the sheets to match specific measurements, you can ensure a perfect fit and avoid any unnecessary wastage. Whether you are working on shed windows, carports, shower panels, splashbacks, kitchen tabletops, signage, or shelving, cutting smoked Perspex to size allows for greater flexibility and customization.

Tools for Cutting Acrylic Sheets

While professional tradesmen may use power saws or machine-enabled equipment for cutting acrylic sheets, it is entirely possible to cut Perspex at home with the right tools and techniques. Here are some commonly used tools for cutting acrylic sheets:

- Knife/box cutter: A sharp knife or box cutter can be used for scoring the acrylic sheet and creating a guide line for cutting.

- Table saw: For thicker sheets of acrylic, a table saw provides stability and precision.

- Handsaw: A handsaw can be used for cutting thinner acrylic sheets.

- Power tool cutter: Power tool cutters, such as jigsaws or circular saws, are suitable for cutting thicker acrylic sheets.

The choice of tool will depend on the desired shape and the thickness of the acrylic sheet.

The Cutting Process

Before starting the cutting process, it is important to set up a stable surface and ensure there is ample space around you to avoid accidents or damage. Once the setup is complete, follow these steps:

Scoring

Scoring the acrylic sheet is recommended to create a guide line for cutting. Use a sharp knife or box cutter to score firmly along the desired cutting line, using a ruler or straight edge for accuracy. For thinner sheets (4mm or thinner), scoring the plastic a few times back and forth should be sufficient. After scoring, snap the plastic sheet along the edge of the surface underneath the scoring mark to achieve a clean cut.

Cutting Thick Acrylic

For thicker acrylic sheets, using a power saw or jigsaw is recommended for stability and safety. Trying to cut thicker sheets with a handsaw or knife can be dangerous and may result in incorrect or damaged cuts. Circular saws are also suitable for cutting thicker sheets and can provide efficient and safe results. When cutting around corners or curved edges, a band saw is a better option.

Smoothing the Edges

After cutting the acrylic sheet, it is common for the edges to be rough. To achieve a smooth finish, scrape off any loose elements left over from cutting and then sand or file the edges. Using high grit sandpaper, gently sand down the edges to create a polished finish.

Additional Tips and Recommendations

Here are a few additional tips to consider when working with smoked Perspex:

- Cleaning: Regular cleaning of acrylic sheets is important to maintain their finish. Use soft cloths and avoid chemical cleaning agents that can damage the material. After cutting and sanding the edges, wipe the acrylic sheet with a damp cloth to remove any debris.

- Laser Cutting: Laser cutting is another popular method for cutting acrylic sheets, especially for intricate designs or engraving. Laser cutting is often used for extruded and cast acrylic sheets, as they offer better tolerance and malleability during fabrication.

- Machines for Cutting Acrylics: There are various tools and machinery available for cutting acrylic sheets. These include scoring tools, measuring equipment like spirit levels or rulers, and cutting machines commonly found in workshops or garages.

Smoked Perspex cut to size offers a versatile and customizable solution for a wide range of projects. With the right tools and techniques, it is possible to achieve clean and precise cuts at home. Whether you are a DIY enthusiast or a professional tradesman, understanding the process of cutting and working with acrylic sheets can help you create stunning and functional designs.

If you want to know other articles similar to Cutting and working with smoked perspex: a complete guide you can visit the Cutting category.

Related Articles